How to solve laser cutting air compressor contains oil?

In the process of laser cutting, auxiliary gas is essential. The main functions are:

Combustion-improve cutting efficiency;

Heat dissipation-prevent material hardening;

Purging-The pressurized gas blows off the molten metal slag, prevents dust from clogging the laser nozzle, and protects the optical components such as the focusing lens.

Type of auxiliary gas for laser cutting

At present, three types of auxiliary gas are widely used in the laser cutting industry:

Oxygen: Mainly used for cutting carbon steel materials. Because oxygen is a good combustion aid, it can improve cutting efficiency. However, since a metal oxide film will be formed on the cutting surface, it will have a certain impact on subsequent machining.

Nitrogen: Mainly used for cutting stainless steel. Nitrogen does not react with metals. Therefore, it will not form an oxide film, which is good for subsequent processing. But it is precisely this advantage that leads to low nitrogen cutting efficiency and increased gas consumption.

Compressed air: Compared to oxygen and nitrogen, compressed air is easier to obtain and cheaper. Since the air contains about 20% oxygen and 78% nitrogen, this determines that its cutting efficiency is far less than oxygen, but it is better than nitrogen, and the working surface after cutting is also better than oxygen.

The hourly cost of using compressed air is the lowest. This has not been calculated even when oxygen or nitrogen is used as auxiliary gas, the other processes of laser cutting equipment also need compressed air. Therefore, it is the most economical to use compressed air as the auxiliary air when the work-piece is allowed.

Air compressor for laser cutting machine

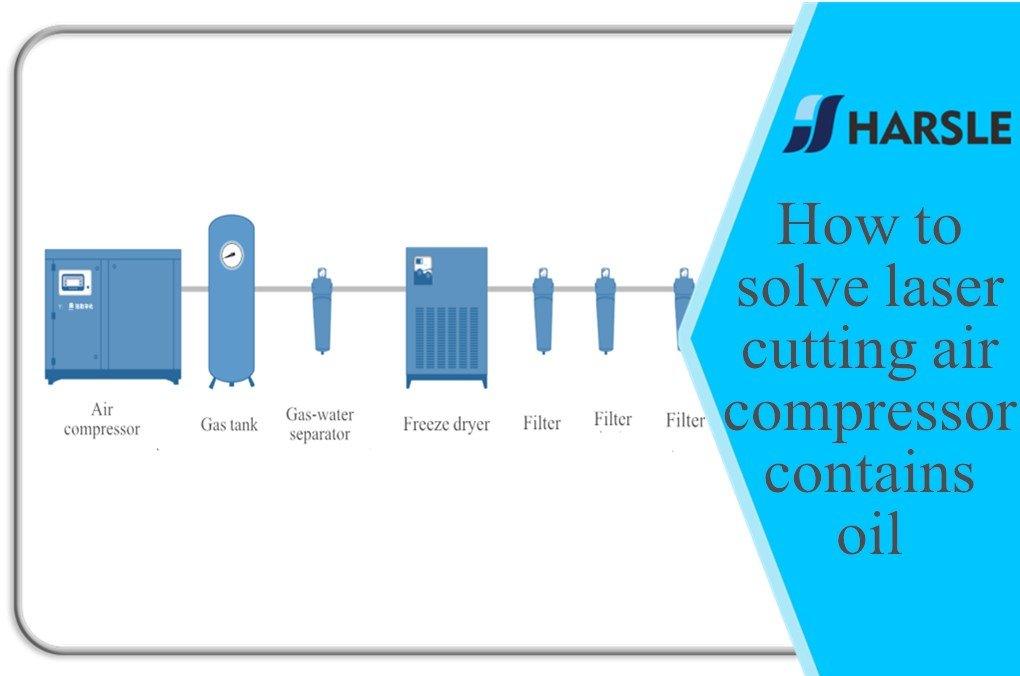

The above picture is a relatively common equipment for laser cutting machines on the market. This equipment is a device that integrates water removal, dust removal, and buffer tank. It is easy to install and eliminates the need for customers to provide gas storage tanks, cold dryers, and filters. The trouble of the device and the after-sales service is also convenient.

The main process is shown in the figure. An oil removal filter is added at the back end of the air storage tank. Most of the liquid water can be removed through the condensation and water removal filter of the air storage tank, and then the compressed air is compressed through a refrigerated dryer. The dew point is reduced to about 5℃, and finally the residual liquid oil and dust are filtered through the multi-stage filter at the rear end. Finally enter the laser cutting equipment.

This configuration treats the water and dust in the compressed air well, and can meet the demands of laser cutting machine. However, it ignores the influence of oil, and only deals with the treatment of liquid oil. Failure to purify the gaseous oil in the compressed air will cause the compressed air to blow the molten slag, and the compressed air will rapidly condense when the pressure is released. When the pressure is released and the temperature is reduced, it condenses into liquid oil, thus contaminating the laser cutting equipment.

Compressed air contains water mist and oil. If it is not cleaned up, the oil-water mixture in it will contaminate the protective mirror, slightly affect the efficiency of laser cutting, or disperse the laser focus, resulting in impenetrable products and waste products. In severe cases, it may even cause damage to the high-energy laser head and cause greater economic losses.

air compressorair compressorair compressorair compressorair compressorair compressor