วิธีแก้ปัญหาตะกรันเชื่อมเมื่อตัดเหล็กคาร์บอนด้วยเครื่องตัดเลเซอร์?

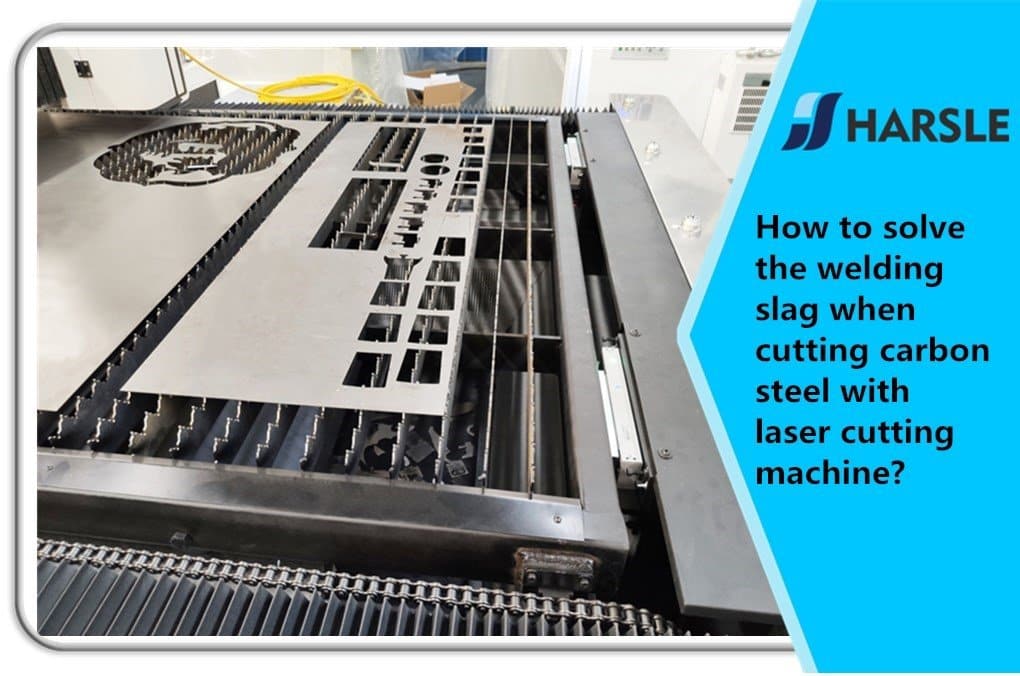

Carbon steel has always been one of our common metal materials, and we have always used laser cutting machines for processing. But many people have reported that how to solve the problem of welding slag when cutting carbon steel with เครื่องตัดเลเซอร์? This problem is a relatively common problem in the use of laser cutting machines, so what should I do if I encounter such a situation?

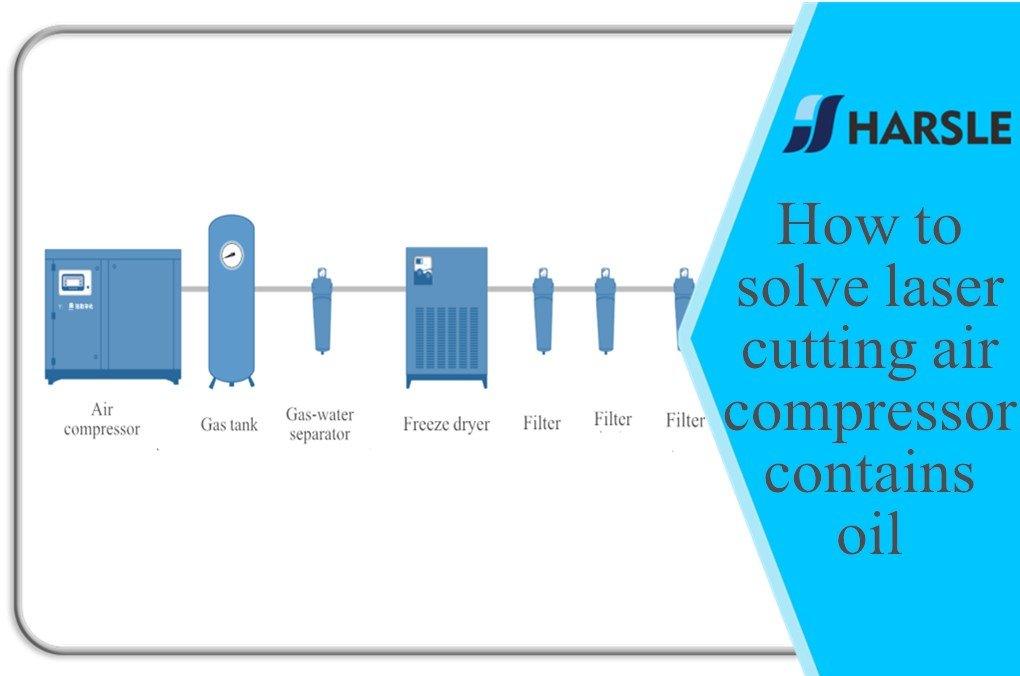

The auxiliary gas pressure is too low. In addition to the purpose of cooling and combustion, the auxiliary gas also needs to blow away the slag. When the auxiliary gas company does not reach a certain standard threshold, it is impossible to completely remove all the slag produced by cutting and melting. Blow off, so before cutting processing, you need to check whether the auxiliary gas pressure is normal and whether the auxiliary gas is used up. If such a situation exists, it must be maintained in time to avoid affecting the cutting quality.

The thickness of the carbon steel material exceeds the cutting range of the laser cutting machine. Because the temperature of the laser cutting reaches more than 1700 degrees Celsius at the moment the beam irradiates the surface of the workpiece, it will melt the material in the area and produce boiling slag. The boiling phenomenon will also bring a part of the oxygen to the lower area of the reaction zone, and under the action of oxygen-assisted combustion, the lower part of the area produces a combustion reaction to realize the cutting of materials.

However, if the thickness of the carbon steel material is too large, there is no oxygen at the melting point of the lowermost layer, so that the material at the lowermost layer cannot form a combustion reaction, and it is mainly melted by the heat generated by the combustion reaction in the upper area. But in fact, it is not completely melted. So no matter what kind of high-pressure auxiliary gas can not blow away the slag.

In addition, it is worth mentioning that in view of the above situation, usually when using a เครื่องตัดเลเซอร์ to cut thicker carbon steel plates, oxygen is used as an auxiliary gas. On the one hand, it serves the purpose of cooling and blowing away the slag, and at the same time. For the purpose of supporting combustion, it realizes thicker carbon steel material cutting and perfect quality cutting. welding slag

Welding is a fundamental joining process used in various industries, from construction to aerospace. In the welding world, one often encounters a byproduct known as welding slag. This residue plays a crucial role in the welding process but also requires proper handling and removal to ensure the quality and integrity of the weld. In this comprehensive guide, we will delve into the world of welding slag, exploring its formation, functions, importance, and methods for effective removal.

Section 1: Formation of Welding Slag (200 words)

Welding slag is a non-metallic residue that forms during the welding process, particularly in arc welding methods like Shielded Metal Arc Welding (SMAW), also known as stick welding. The formation of welding slag is intimately tied to the use of flux. Flux is a material that coats the welding electrode or is present in the welding wire. This flux serves multiple essential purposes in welding.

During welding, the flux coating on the electrode or the flux-core wire melts alongside the electrode and base metal. As the materials melt and fuse, the flux undergoes a chemical reaction, creating a molten slag. This slag floats to the surface of the weld pool and solidifies as the weld cools. The result is a glassy or crystalline material covering the surface of the weld.

Section 2: Functions of Welding Slag (200 words)

Welding slag is not merely a waste product; it serves several vital functions in the welding process:

- Shielding: Welding slag acts as a protective barrier, shielding the weld pool and molten metal from atmospheric contamination, primarily oxygen and nitrogen. This shielding prevents the formation of defects like porosity and inclusions in the weld.

- Arc Stabilization: The flux coating helps establish and maintain a stable arc between the welding electrode and the workpiece, essential for a consistent and controlled welding process.

- Impurity Removal: Welding slag promotes the removal of impurities and oxides from the base metal. By facilitating this purification process, it contributes to the overall quality of the weld.

Section 3: Importance of Removing Welding Slag (200 words)

While welding slag plays crucial roles during welding, its removal is equally significant. Failing to remove welding slag can lead to several adverse effects:

- Slag Inclusions: If welding slag remains trapped within the weld metal, it can result in the formation of slag inclusions. These inclusions weaken the weld and diminish its mechanical properties.

- Aesthetic Impact: Welding slag often leaves a rough, uneven surface on the weld bead, affecting the appearance of the weld. For applications where aesthetics matter, proper slag removal is crucial.

- Incomplete Fusion: Thick layers of slag can impede complete fusion between the weld metal and the base metal, potentially compromising the weld’s structural integrity and strength.

Section 4: Methods for Removing Welding Slag (300 words)

Removing welding slag is a standard practice in welding, and various methods are employed:

- Chipping: After the weld has cooled, a welding hammer or chipping hammer is used to gently strike the slag layer. This causes the slag to fracture and break away from the weld bead. Chipping should be done carefully to avoid damaging the underlying weld.

- Wire Brushing: A wire brush, often referred to as a slag brush, is employed to sweep away any remaining slag particles from the weld. It also helps in cleaning the surface of the weld bead, leaving a smoother finish.

- Grinding: In cases where the slag is stubborn or adheres firmly to the weld, grinding tools such as a grinder or a chisel can be used to remove it. Grinding provides a more aggressive approach to slag removal.

- Washing or Blasting: In some applications, particularly those requiring high cleanliness standards, washing or blasting with abrasive materials like sand or steel shot may be used to remove residual slag and contaminants.

Section 5: Safety Considerations (100 words)

It’s crucial to prioritize safety when handling welding slag:

- Always wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and protective clothing to prevent injury from flying slag particles or sharp edges.

- Ensure proper ventilation in the workspace to remove fumes and gases produced during the welding process and slag removal.

- Maintain a clean work area to prevent tripping hazards and accidents.

Conclusion (100 words)

Welding slag is a fascinating byproduct of the welding process, with functions that contribute to the success of a weld. However, its removal is equally important to ensure the weld’s structural integrity, appearance, and overall quality. Understanding the formation, functions, and removal methods of welding slag is crucial for welders and welding professionals, as it contributes to the production of strong and reliable welds that meet industry standards and requirements.