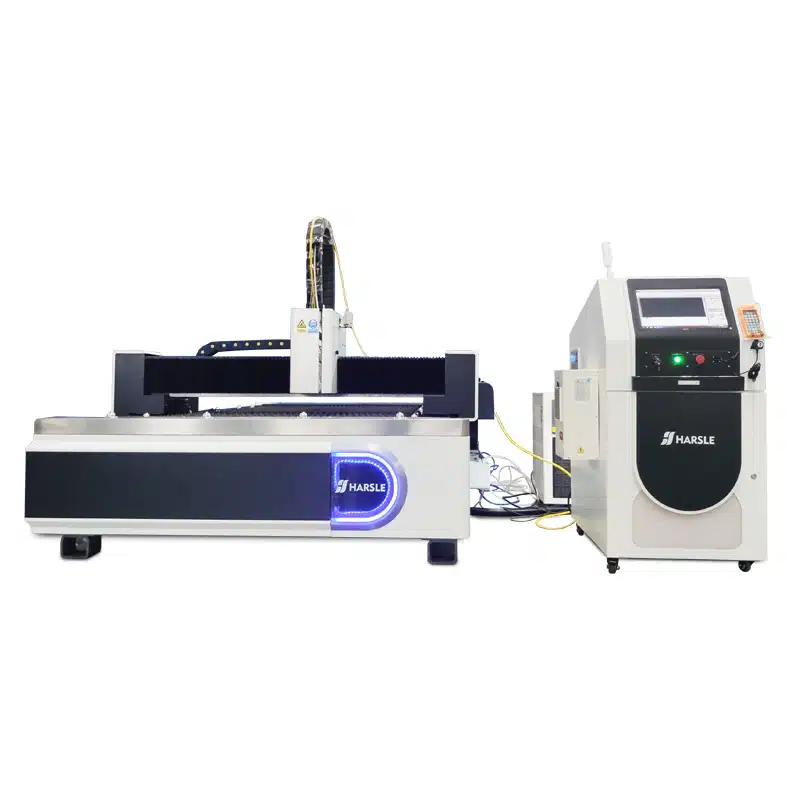

Metal Sheet And Plate Fiber Laser Cutting Machines With CNC Control

| Capacity |

1000W |

|---|---|

| Lead Time |

7 Days |

| Table Size |

1500mm*6000mm |

| Payment Method |

LC ,T/T |

| Function |

Cutting |

| Price Item |

EXW ,FOB |

| Laser Source |

IPG |

| Laser Head |

Raytool |

| Brand |

HARSLE |

15

People watching this product now!

Description

Metal sheet and plate fiber laser cutting machines with CNC control are available for all metal cutting, especially for stainless steel, iron, aluminum, copper, and other metal material cutting. Widely used in sheet metal, metal products, steel structure, precision machinery, auto parts, glasses, and so on.

Laser Source

Laser Head

Main Features

- Laser heads keeping a distance from the workpiece in the cutting process can reduce collision risks. It will stop cutting when the colliding plate.

- It is suitable for cutting carbon steel, stainless steel, aluminum, brass, and alloy metal materials.

- An automatic lubricating device is mounted to ensure a smooth machine operation with low noise.

- The system will start a full abnormal alarm and push it to the interface through the control center when equipment is abnormal.

- Auxiliary gas low-pressure alarm function Providing real-time pressure detection, pushing abnormal information when pressure value is lower than optimal cutting effect and precision.

- A professional CNC system and cutting software support CAD drawing and text programming.

- High carbon content, high compressive strength, and high hardness worktable.

- Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in use.

- The machine owns a more comfortable operation, more stable performance, more durable quality, higher cutting efficiency, and wider application scope.

Machine Constructions

- Fiber laser cutting machine body: The machine body is made of a machine cabinet, transom, working table, and Z-axis device, operation controlling parts and gas, chiller.

- Machine cabinet: Adopting the whole bed welding technique, the machine cabinet is strong wearable, and stable. X 、 Y-axis adopting servo motor, and with high accurate reduction gears and good quality gear. It can effectively guarantee the machine’s transferring accuracy. Besides, it is equipped with an automatic lubricating system, dusting collecting system, and is better for getting out of waste.

- Transom: Adopting vessel quality style steel material, less weight, but with a better application, it can guarantee transom to be strong, wearable, and stable features.

- Working table: Whole casted steel body is also equipped with a ball on every side to facilitate a better feeding job. Attention:Optionally equip with up and down feeding devices to protect material safety and crash.

- Z-axis up and down: When the machine cutting head moves to the surface of the material. It will transfer the signal to the controlling system. So that it can effectively control the best distance between the cutting head and the material surface.

- Gas and chiller system: There are two kinds of gas, one part is to offer gas for machine cutting. such as compressed air, nitrogen, and oxygen gas, the other one is to facilitate to compress the air, for example, the exhauster gear gasket and the working table fastening claw.

- The Chiller system is made of two parts: cooling water will enter into two parts. One is to enter the cutting head location to protect QBH, and another one is to protect the laser source to cool it down and then return it to the water chiller.

- Cutting head and following system: With automatic focal length following system. The machine head can automatically keep the best distance between the cutting head. The material to get the best cutting technique.

- CNC controlling system: Controlling system can admit Windows XP Professional and Windows 7. So that it can control the machine cutting with required parameters.

Reviews (0)

Be the first to review “Metal Sheet And Plate Fiber Laser Cutting Machines With CNC Control” Cancel reply

About HARSLE

Why Choose HARSLE?

HARSLE is a professional metalworking machine manufacturer in China for many years, our productions have been sold to over 100 countries in the world!

SKU:

LC23032253

Category: Open-Type Laser Cutter

Tags: cutting machines with CNC control, laser cutting machines, sheet metal cutting machines

Related products

1000W Metal Stainless Steel Carbon Sheet Fiber Laser Cutting Machine

Rated 4.00 out of 5

Reviews

There are no reviews yet.