Due tipi di dispositivi di saldatura laser che dovresti conoscere

Tempo di lettura stimato: 10 minuti

Laser-arc hybrid welding device and process mode

Laser hybrid welding technology refers to a hybrid welding technology that combines laser and other welding methods. Its advantage is that it can give full play to the advantages of each welding method and overcome some shortcomings. For example, because the price-to-power ratio of laser welding is too large, when deep penetration and high-speed welding of thick plates, in order to avoid the use of expensive high-power lasers, low-power lasers can be combined with conventional gas shielded welding for composite welding.

Laser Welding Device

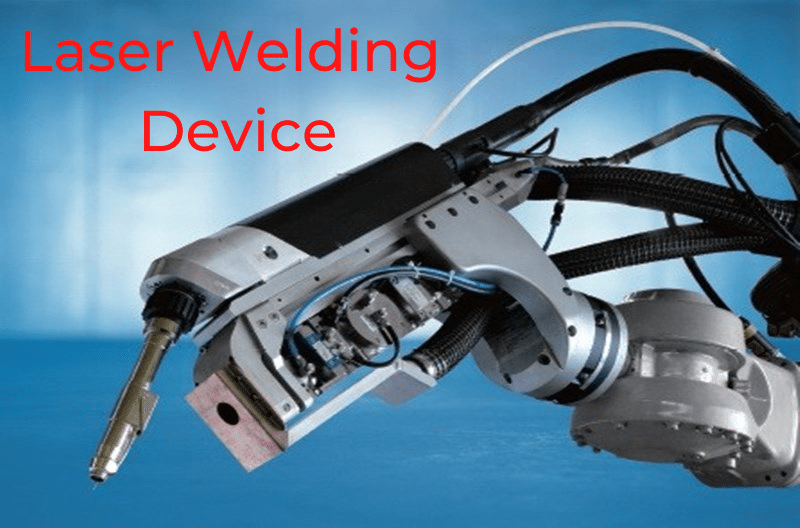

Laser-arc hybrid welding equipment

As soon as laser-arc hybrid welding appeared, it attracted the attention of many welding workers, so R & D work was carried out one after another. There are many forms of laser arc hybrid welding equipment. Figure 3.1 (a) shows the laser-MIG/MAG hybrid welding system. The hybrid welding system consists of the following parts.

- Laser-MIG/MAG hybrid welding head, as shown in Figure 1.1(b).

- MIG/MAG welding system (including power supply, wire feeding mechanism and welding wire reel).

- Laser and its light guiding, focusing and transmission system.

- Welding robot and its control box.

- Remote control.

In addition, there are protective gas, workbench, control system, etc.

The hybrid saldatura head, also known as the hybrid welding gun, is a component that combines the laser beam and the arc heat source, through which the relative position between the two can be flexibly adjusted (such as the distance between the optical filaments, the angle between the optical filaments, the sequence of lasers and arcs, etc.), Realizing the effective coupling of the two heat sources is a key component of the hybrid welding equipment.

Laser Welding Device

Commercial composite welding torches have been launched on the market, such as the coaxial composite welding torch of Mitsubishi Heavy Industries of Japan and the composite welding torch of Fronius of Austria that can be easily connected to the robot [Figure 1.2 (a)], and the research and development of Fraunhofer Research Institute in Germany Laser-MIG paraxial hybrid welding torch based on the principle of “integrated nozzle” [Figure 1.2 (b)], the welding torch is tightly fixed by pipes, and the outside of the laser and arc is protected by a circular water-cooled copper sleeve. The angle between the laser and the MIG welding torch is 15℃~30℃, it can make the two heat sources close to the maximum, thereby reducing the volume of the compound welding gun, making the use of the welding gun more flexible, and easy to realize three-dimensional automatic welding.

In addition to the conventional hybrid welding system, the researchers also developed a synchronous modulation laser-arc hybrid welding system (HybSy). The system has the following characteristics: laser arc control mechatronics, the process synergy is further expanded, the welding speed is faster, the application range of processing materials is wider, and the three-dimensional processing ability is stronger. The test results show that when surfacing 6mm thick medium-strength steel plates, Under the same process conditions, HybSy is 40% higher than conventional hybrid welding penetration.Laser Welding Device

Laser-arc hybrid welding working mode

For laser-MIG hybrid welding, according to the different heat input ratios of the two heat sources, the physical mechanism and process mode are also different. According to the size of the laser power in hybrid welding, laser-arc hybrid welding can be classified into three categories; 100-watt laser arc composite, 1000-watt laser arc composite, and 10,000-watt laser arc composite.

100-watt laser arc hybrid welding

Mainly show the characteristics of arc welding, no small holes are produced during the welding process. Low-power laser energy mainly plays the role of stabilizing and compressing the arc and improving the utilization of arc energy, avoiding the arc drift phenomenon that occurs under the conditions of high welding speed in general MIG welding, and can suppress the occurrence of defects such as hump and undercut, thereby greatly improving The welding speed is more suitable for high-speed welding of thin plates. This kind of hybrid welding mode has low cost and has attracted more and more attention.

10,000-watt laser arc hybrid welding

Mainly show the characteristics of laser deep penetration welding, the weld has a larger aspect ratio. It is difficult to realize all-position flexible welding with the combination of 10,000-watt high-power CO2 laser and MIG welding. The main application directions are tailor welding of large flat ship plates and welding of ribs. Due to the large investment in equipment (above ten million yuan), it is temporarily difficult to popularize and apply it on a large scale.

1000-watt laser-arc hybrid welding

It has the characteristics of both laser welding and arc welding and can give full play to the advantages of both. It is mostly used for laser-MIG composites. It is suitable for aluminum alloy, magnesium alloy, carbon steel, stainless steel, low-alloy high-strength steel, ultra-high-strength steel, and other materials. For the welding of medium and thick plates, the investment in kilowatt-level laser-arc hybrid welding equipment is moderate, and it has good adaptability to different welding structures and has a wide range of application prospects. It is a laser arc hybrid heat source technology that meets my country’s national conditions.

Laser brazing process

Laser brazing is a brazing technology in which the laser is used as a heat source to heat the fiber material to melt it. The main feature of laser brazing is to use the high energy density of the laser to achieve rapid heating of local or small areas to complete the brazing process. Figure 1.3 shows the joint form and wire feeding method of laser brazing.

According to the different heating temperatures, laser welding is divided into soft soldering and brazing. Solder whose liquidus temperature is lower than 450℃ is called soft soldering, which is mainly used for the connection of printed circuit boards and electronic components; solder whose liquidus temperature is higher than 450℃ and lower than the melting point of the base metal for brazing, it is mainly used for the connection of structural steel and galvanized steel. Laser brazing also has advantages in the connection of non-ferrous metals. Most of the non-ferrous metals have higher reflectivity to the laser, and the thermal conductivity of the material is higher. Laser melting and welding require higher power. Laser brazing of silver, copper, nickel, gold, aluminum, and other non-ferrous metals has good results. The brazing seam structure is small and joint performance is good.Laser Welding Device

The brazing filler metal during laser fiber welding can be preset or wire feeding. The brazing heating temperature is low, and the requirement of laser power density is low, so the defocusing method is generally used for heating. In this way, the power density can be reduced, and the spot size and shape can be adjusted according to the size of the brazing seam. Laser brazing joints usually adopt two methods: crimping butt joint and lap joint. In the case of crimping butt joints, the feeding of the solder from the laser front end is conducive to the stability of the brazing process; in the case of lap joints, the feeding of the solder horizontally from the bottom of the side is conducive to the stability of the brazing process.Laser Welding Device

Laser brazing can use a single beam or dual beams. The dual-beam can be obtained either by two independent lasers or by a laser beam splitter. Double beam brazing can control the irradiation time and position more flexibly and conveniently, and better control the brazing process. The laser irradiation mode of double beam laser brazing overlap, butt, and crimp butt is shown in Figure 1.4.

In the case of double-beam laser overlap, one laser beam heats and melts the welding wire, and the other laser beam heats and fills the gap to increase the temperature of the base material, promote the wetting and spreading of the fiber, and increase the strength of the joint. In the case of docking, two laser beams are irradiated and heated by overlapping, in addition to improving the effectiveness of heating the solder, the area near the joint is also heated and heated at the same time, which promotes the wetting, spreading, and uniform distribution of the needle material.

The main technological parameters of laser brazing are as follows.

- Laser power. Both CO2 laser and YAG laser can be used for laser brazing, and their respective characteristics during brazing are the same as those of laser fusion welding.

- Spot diameter. Laser brazing usually uses a defocused spot, and the size of the spot depends on the width of the brazing seam.

- Brazing speed. According to the actual brazing requirements, it depends on laser power. The greater laser power, the faster the brazing speed.

- Wire feeding speed. Its size is mainly considered brazing seam filling and good forming. The wire feeding speed should be matched with brazing speed, and wire feeding speed should be increased while increasing brazing speed.

In addition, the laser incident angle, wire feeding angle, solder shape, and size are also processed parameters of laser brazing.

When laser brazing, the choice of brazing filler metal, flux, and shielding gas is basically the same as that of conventional brazing. In most cases, laser brazing can be done without flux and shielding gas.

The key to laser brazing is to reasonably control the distribution of laser power. The laser beam converges on the solder, and the temperature of the solder is too high, which leads to too fast melting. The insufficient temperature of the base material makes the solder not wet the base material well, which affects the filling effect and deteriorates the formation of the brazing seam. The laser beam is concentrated on the base material. The temperature of the solder may be too low to reduce the fluidity or activity of the solder. The base material may be overheated and melt, causing the solder to directly enter the molten pool to form a fusion weld. The brittle phase formed also affects the performance of the brazing joint.

Laser soldering is mainly used for the connection of electronic components and printed circuit board integrated circuits. Laser radiation is used to heat the leads of the integrated circuit, and heat is transferred to the substrate through the solder or the preset solder. When the soldering temperature is reached, the flux and the solder melt, and the substrate and leads are wetted to form a connection. YAG lasers are mostly used for laser soldering of integrated circuits.

The semiconductor laser is a direct electron-photon converter with direct modulation capability. The conversion of pulsed laser and continuous laser can be realized by adjusting the power output. The output wavelength of the semiconductor laser is 808nm, which is shorter than that of the YAG laser, which is more conducive to the absorption of the laser by the solder and improves the heating efficiency. The characteristic of semiconductor laser brazing is that it will not have a thermal effect on the components to be welded, and the laser temperature field is limited to the lead range. The fluidity of the solder can be effectively controlled, avoiding the solder bridging between fine-pitch leads.

Laser Welding Device Laser Welding Device Laser Welding Device Laser Welding Device Laser Welding Device Laser Welding Device Laser Welding Device Laser Welding Device Laser Welding Device Laser Welding Device Laser Welding Device Laser Welding Device Laser Welding Device Laser Welding Device

Well done

Nice article, can I buy laser welding machine from you?

Yes, I will send catalog to you.